Some thoughts on ALRDC and rebooting the future of rod pump automation

Author: Charles-Henri Clerget•Published: September 25, 2025

Last week, I had the pleasure of attending the Artificial Lift R&D Council (ALRDC) rod pumping workshop along with other members of the Amplified team. We flew down to Midland to listen to two days of presentations about the newest rod lift products being rolled out, listen to operators’ feedback on their latest field trials and give a talk of our own on variable frequency drive (VFD) optimization.

To us, ALRDC events stand out as some of the best in the industry in terms of technical stature of the attendee group, which is why we have become regulars over the years and decided to sponsor this year’s workshop. I particularly enjoyed the presentations given by Jeff Saponja on solid separation in horizontal wells and Jeff DaCunha on the application of inverse problem methodologies for diagnostic of downhole conditions.

Overall, two main points stood out to me this year.

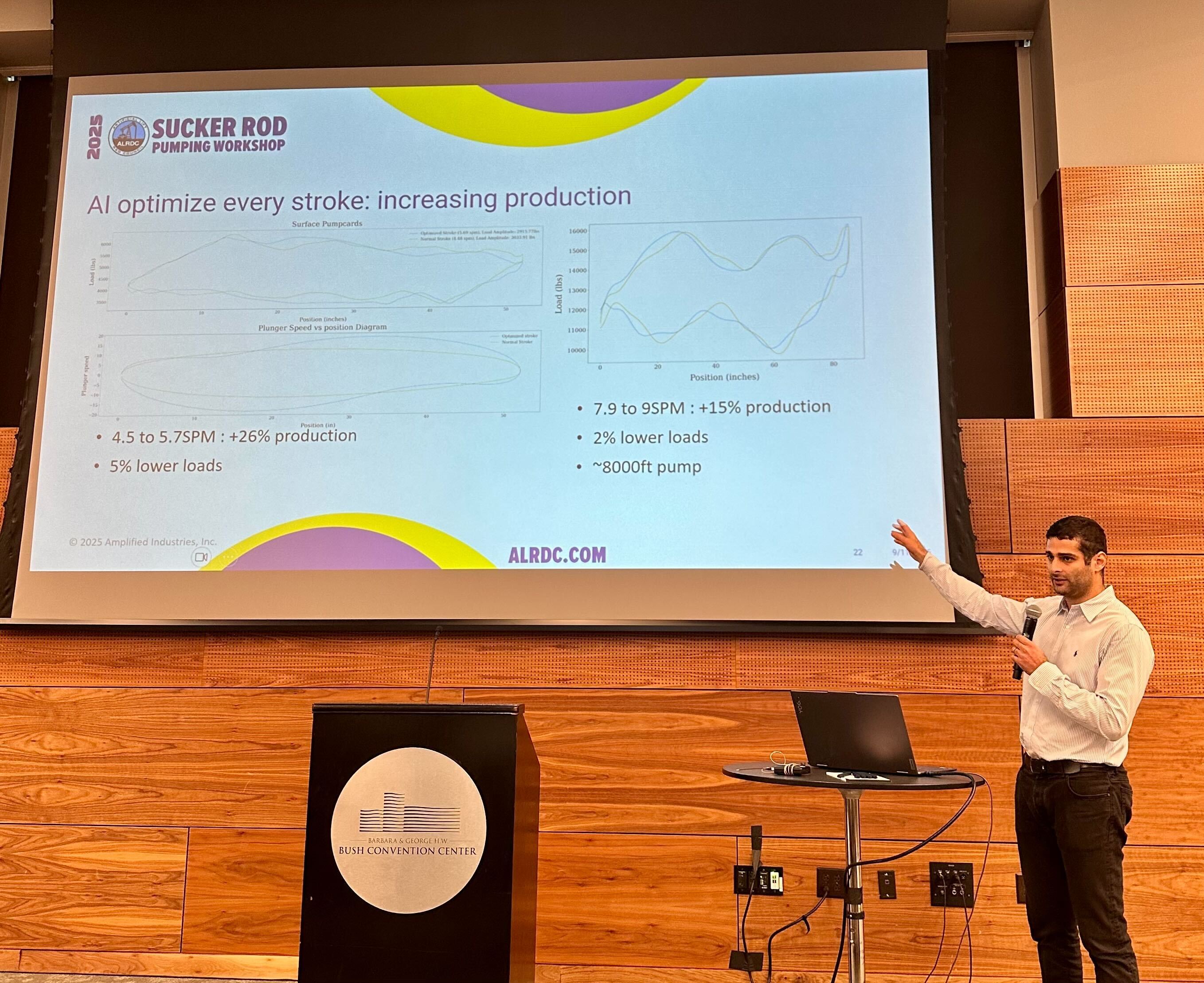

The first one is that while Artificial Intelligence (AI) has become a hot topic and a corporate buzzword, on the ground, operators are still confused about how they will use it to improve their day-to-day processes. Sébastien, my business partner and Amplified’s CEO, himself was sitting on a panel discussing the impact of AI in our field. During the Q&A, we heard a lot of questions from the audience regarding the difference between data science, machine learning and Generative AI, the extent to which AI can be trusted for decision-making and how to pick the first practical use cases to apply it. Our own talk was focused on the application of AI to the closed-loop optimization of VFDs. The goal is to engineer the VFD’s frequency profile so the pumping unit speeds up and down at the exact right time within each stroke to cancel stress oscillations in the rod; this increases fluid production while reducing equipment wear. More broadly, a lot of machines have tunable parameters that can improve performance but operators don’t customize because the amount of time required to baby sit the process would be prohibitive. By taking humans out of those loops, AI enables us to fully leverage existing hardware and achieve those benefits at scale.

The second one is the change in attitude around the type of rod pump wells that should be considered for automation projects. Historically, a lot of stripper wells (aka low-flow or marginal wells) have been systematically overlooked on account of the fact that the production of those wells cannot justify the investment in a pump-off controller (POC) or even a basic SCADA system. It has always seemed to me that the benefits of POCs in that market were underestimated. Indeed, a large fraction of the economic value of those controllers comes not from increased production but rather from reduced costs in the form of lower electricity bills and less frequent downhole failures. Since workover rig crews don’t care about the production of the well they fix when billing for hours, it seems to me that a lot of the economics should play out in the same way for a roaring gusher or a humble stripper. Be that as it may, the lack of simple, affordable automation solutions has certainly slowed down adoption for those assets, and for many years, legacy vendors didn’t seem to think that this market was worth their time. On the contrary, Amplified was built on the thesis that a great business could be created upon delivering such a streamlined product.

While I have long felt vindicated by the commercial traction that we have enjoyed (5,000 IoT devices shipped in the last 12 months, and doubling that number every year), imagine my surprise then seeing this year’s line up filled with talks such as “A Cost Effective Diagnostic Solution For Marginal Sucker Rod Pump Wells” or heavy hitters like Weatherford presenting a novel IoT device with the express purpose of retrofitting legacy SAM 1.0 controllers and bringing them into the 21st century. Of course, the pièce de résistance was seeing SLB dedicate its talk to “Low-Cost Pump-Off Control for Marginal Wells”. Low-cost and Schlumberger are not words that I had grown accustomed to hearing in the same sentence; truly, everything must change so that everything can stay the same.

Judging by their communication, the caliber of the presenters attending the conference and overall sales effort, it seems clear that SLB has decided to commit significant resources to enter this new segment and challenge Lufkin’s historical market dominance. I have no doubt that Lufkin will rise to the occasion and that they’ll soon also be working on their own cloud-native, IoT device. Having operated for 6 years in this ecosystem, I don’t think any of the competing offerings rivals the product we have built in terms of simplicity, AI capabilities or overall performance. But it is a sign of the times that even big corporations are now making bold moves to try and catch up. As iron sharpens iron, I expect innovation to speed up in the space while oil producers stand to be the big beneficiaries!

Last but not least, the Bush Convention Center being but a couple minutes walk from Pachuco’s, I was able to treat myself to an outstanding round of smoked suadero. For those not familiar with this rising Midland institution, I highly recommend you pay them a visit. While they always seem to be overflowing with local oilmen, do not let the line discourage you; their barbecue is well worth the wait.